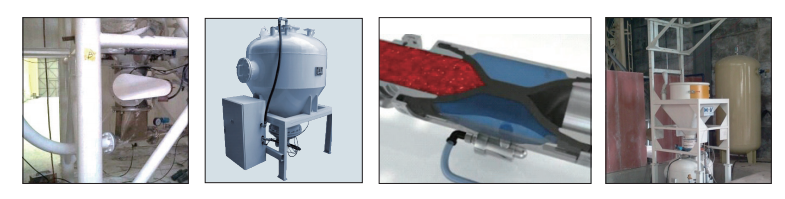

密(mi)相氣力(li)輸(shu)送系列

氣力輸送原理

氣(qi)(qi)(qi)力(li)輸(shu)(shu)送(song)(song)(song)系統(tong)(tong)可分(fen)(fen)(fen)類(lei)為(wei)不同(tong)(tong)的(de)(de)(de)(de)(de)(de)流(liu)(liu)動(dong)(dong)型(xing)式(shi)(shi)(shi),其(qi)中(zhong)兩種(zhong)主要型(xing)式(shi)(shi)(shi)是:(a) 稀(xi)相(xiang)輸(shu)(shu)送(song)(song)(song)和(b)密(mi)(mi)相(xiang)輸(shu)(shu)送(song)(song)(song)每種(zhong)流(liu)(liu)動(dong)(dong)型(xing)式(shi)(shi)(shi)可按物(wu)料(liao)(liao)與空氣(qi)(qi)(qi)的(de)(de)(de)(de)(de)(de)流(liu)(liu)量比(bi)率大(da)小分(fen)(fen)(fen)類(lei),其(qi)比(bi)率也(ye)被(bei)(bei)(bei)稱(cheng)為(wei)“固氣(qi)(qi)(qi)比(bi)”: μ=ms/mf (1)許多稀(xi)相(xiang)的(de)(de)(de)(de)(de)(de)運(yun)行范圍為(wei)0<μ<15,而(er)(er)密(mi)(mi)相(xiang)通常(chang)是μ>15。圖1所示的(de)(de)(de)(de)(de)(de)是典型(xing)輸(shu)(shu)送(song)(song)(song)狀態圖。稀(xi)相(xiang)輸(shu)(shu)送(song)(song)(song)可以(yi)(yi)被(bei)(bei)(bei)認(ren)(ren)為(wei)是一(yi)種(zhong)完全(quan)的(de)(de)(de)(de)(de)(de)懸(xuan)浮(fu)流(liu)(liu),而(er)(er)密(mi)(mi)相(xiang)輸(shu)(shu)送(song)(song)(song)通常(chang)被(bei)(bei)(bei)認(ren)(ren)為(wei)是非(fei)懸(xuan)浮(fu)流(liu)(liu)。然而(er)(er),如圖1所示,許多不同(tong)(tong)種(zhong)類(lei)的(de)(de)(de)(de)(de)(de)密(mi)(mi)相(xiang)(非(fei)懸(xuan)浮(fu)流(liu)(liu))依靠散料(liao)(liao)的(de)(de)(de)(de)(de)(de)料(liao)(liao)性(xing)和流(liu)(liu)動(dong)(dong)性(xing)存在(zai)(zai)。密(mi)(mi)相(xiang)輸(shu)(shu)送(song)(song)(song)同(tong)(tong)樣也(ye)能(neng)被(bei)(bei)(bei)定義(yi)為(wei)輸(shu)(shu)送(song)(song)(song)物(wu)料(liao)(liao)完全(quan)填(tian)滿管道(dao)(dao)截(jie)面(mian)的(de)(de)(de)(de)(de)(de)一(yi)種(zhong)輸(shu)(shu)送(song)(song)(song)方式(shi)(shi)(shi)。稀(xi)相(xiang)輸(shu)(shu)送(song)(song)(song)通常(chang)需要使用大(da)量的(de)(de)(de)(de)(de)(de)高(gao)速(su)(su)氣(qi)(qi)(qi)體(ti)。氣(qi)(qi)(qi)流(liu)(liu)依靠升(sheng)力(li)和推動(dong)(dong)力(li)以(yi)(yi)離散粒子的(de)(de)(de)(de)(de)(de)形式(shi)(shi)(shi)攜帶著物(wu)料(liao)(liao)。參考圖1中(zhong)所述的(de)(de)(de)(de)(de)(de)“懸(xuan)浮(fu)流(liu)(liu)”,稀(xi)相(xiang)系統(tong)(tong)通常(chang)是最(zui)為(wei)被(bei)(bei)(bei)廣泛應用的(de)(de)(de)(de)(de)(de)氣(qi)(qi)(qi)力(li)輸(shu)(shu)送(song)(song)(song)系統(tong)(tong)。由于(yu)稀(xi)相(xiang)系統(tong)(tong)設計的(de)(de)(de)(de)(de)(de)相(xiang)對簡單性(xing),它們(men)同(tong)(tong)時(shi)也(ye)被(bei)(bei)(bei)頻繁的(de)(de)(de)(de)(de)(de)應用在(zai)(zai)工業領域。輸(shu)(shu)送(song)(song)(song)氣(qi)(qi)(qi)體(ti)的(de)(de)(de)(de)(de)(de)速(su)(su)度(du)減(jian)少到比(bi)保持粒子懸(xuan)浮(fu)狀態的(de)(de)(de)(de)(de)(de)臨(lin)界值更小時(shi),導致物(wu)料(liao)(liao)在(zai)(zai)輸(shu)(shu)送(song)(song)(song)管道(dao)(dao)的(de)(de)(de)(de)(de)(de)橫截(jie)面(mian)形成不均(jun)勻的(de)(de)(de)(de)(de)(de)分(fen)(fen)(fen)布(bu)。臨(lin)界氣(qi)(qi)(qi)體(ti)速(su)(su)度(du)被(bei)(bei)(bei)稱(cheng)為(wei)是水(shui)(shui)平(ping)輸(shu)(shu)送(song)(song)(song)的(de)(de)(de)(de)(de)(de)跳躍(yue)速(su)(su)度(du),垂直輸(shu)(shu)送(song)(song)(song)時(shi)堵(du)塞。當水(shui)(shui)平(ping)管道(dao)(dao)中(zhong)的(de)(de)(de)(de)(de)(de)物(wu)料(liao)(liao)表面(mian)氣(qi)(qi)(qi)體(ti)速(su)(su)度(du)低于(yu)突變速(su)(su)度(du)時(shi),輸(shu)(shu)送(song)(song)(song)將會(hui)以(yi)(yi)低流(liu)(liu)量通過管道(dao)(dao)橫截(jie)面(mian)的(de)(de)(de)(de)(de)(de)上(shang)部,在(zai)(zai)管道(dao)(dao)的(de)(de)(de)(de)(de)(de)剩余部分(fen)(fen)(fen)以(yi)(yi)高(gao)濃度(du)低速(su)(su)度(du)的(de)(de)(de)(de)(de)(de)形式(shi)(shi)(shi)填(tian)充。有(you)時(shi)沿管道(dao)(dao)的(de)(de)(de)(de)(de)(de)橫截(jie)面(mian)會(hui)被(bei)(bei)(bei)填(tian)滿,而(er)(er)有(you)時(shi)只(zhi)是部分(fen)(fen)(fen)被(bei)(bei)(bei)填(tian)滿.

實際應用(yong)中(zhong), 按照(zhao)氣力(li)(li)(li)驅動形式可(ke)以分(fen)為負壓和(he)正(zheng)壓氣力(li)(li)(li)輸(shu)(shu)送(song), 在這兩(liang)種輸(shu)(shu)送(song)系統中(zhong), 根據流動狀(zhuang)態圖再區分(fen)分(fen)為稀相, 密相和(he)流化態輸(shu)(shu)送(song)系統. 除此之外(wai),根據喂(wei)料不同(tong)分(fen)為連(lian)續(xu)和(he)批次輸(shu)(shu)送(song). 在高壓密相輸(shu)(shu)送(song)技術中(zhong)常采用(yong)批次的壓力(li)(li)(li)罐(guan)進行高壓輸(shu)(shu)送(song), 同(tong)時, 可(ke)以組(zu)合兩(liang)個壓力(li)(li)(li)罐(guan)設(she)計達到連(lian)續(xu)的輸(shu)(shu)送(song).

密相氣力(li)輸送特點:

● 用(yong)氣量小, 節能

● 無(wu)殘留(liu)輸送

● 不堵塞, 運行可(ke)靠

● 維護費用低

● 適合(he)于各類(lei)粉粒(li)物料

● 壓力至0. 6m p a可(ke)調

● 適(shi)合于柔性化自動生(sheng)產中的物(wu)料(liao)高效輸送(song)